- Flywheel to shaft.

- Flywheel to hub (splined).

- Shaft to shaft.

- Floating shaft.

- Many others.

Specifications

Shaft Rating at 2000 rpm |

N/A 75 to 2000 hp |

Capacity per 100 rpm |

N/A 4.05 hp3.02 kW |

| Torque Rating TN1 | N/A 2500 lbs-in282 N-m |

| Approximate Slip Torque2 | N/A 8700 lbs-in900 N-m |

| Torsional Rate kØ3 | N/A 21000 lbs-in/rad2373 N-m/rad |

Axial Rate KA |

N/A 2100 lbs/in368 N/mm |

Radial Rate KR |

N/A 10000 lbs/in1750 N/mm |

Weight Mass |

N/A 6.3 lbs2.87 kg |

Inner Member Inertia |

N/A 0.04 lbs-in-sec20.004 kg-m2 |

Outer Member Inertia |

N/A 0.07 lbs-in-sec20.007 kg-m2 |

| Pilot Outer Diameter4 | N/A 10.340 in262.58 mm |

B.C. Diameter |

N/A 9.625 in244.48 mm |

Diameter C |

N/A 2.813 in71.45 mm |

| Diameter D5 | N/A 3.313 in84.14 mm |

Diameter E |

N/A 2.688 in68.28 mm |

Length F |

N/A 2.00 in50.8 mm |

Length H |

N/A 0.75 in19.1 mm |

Hole Diameter K |

N/A 0.710 in18.03 mm |

Number of Holes L |

N/A 6 |

Hole Size M |

N/A 0.330 in8.38 mm |

Number of Holes N |

N/A 3 |

| Fits SAE Flywheel Number6 | N/A 8 |

Reference Diameter P |

N/A 6.80 in172.7 mm |

Browning Bushing P/N |

N/A Q1 |

Browning Bushing Bore Type 1 Diameter |

N/A 3/4 to 2-1/16 in19.05 to 52.3 mm |

Browning Bushing Bore Type 2 Diameter |

N/A 2-1/8 to 2-11/16 in54.0 to 68.3 mm |

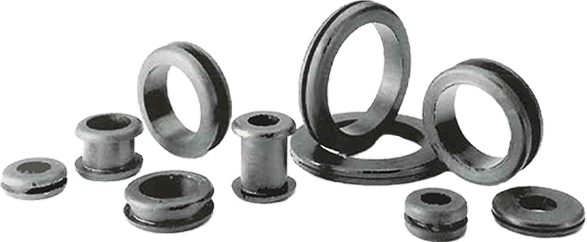

General Description

|

N/A

The Dynaflex coupling line has been developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. These couplings increase equipment life by protecting against torsional vibration, shock and misalignment. Other significant features and benefits are: |

- 1 Prolonged exposure to temperatures in the 0 ºF range and below produces a significantly reduced slip torque prior to driveline warm-up. This condition may result in the coupling's inability to transmit adequate drive torque for applications experiencing unusual cold temperature related parasitic loading.

- 2 Prolonged exposure to temperatures in the 0 ºF range and below produces a significantly reduced slip torque prior to driveline warm-up. This condition may result in the coupling's inability to transmit adequate drive torque for applications experiencing unusual cold temperature related parasitic loading.

- 3 Prolonged exposure to temperatures in the 0 ºF range and below produces a significantly reduced slip torque prior to driveline warm-up. This condition may result in the coupling's inability to transmit adequate drive torque for applications experiencing unusual cold temperature related parasitic loading.

- 4 Pilot diameter tolerances are + 0.000/ -0.005 in. for "A" and + 0.005/ -0.000 in. for "C" diameters.

- 5 Pilot diameter tolerances are + 0.000/ -0.005 in. for "A" and + 0.005/ -0.000 in. for "C" diameters.

- 6 Refer to SAE J620c for flywheel numbers 6-1/2, 10, 11-1/2, 16; to SAE J927a for numbers 60, 80, 100, 120, 160.