|

N/A

Powertrain component life is determined by the load spectrum each component will experience during the machine’s service life. Reciprocating engines, such as spark-ignited gasoline and compression-ignited diesels, produce alternating torque loads which, when superimposed on the steady driving torque, create alternating stresses in driveline system components which shorten component life and reliability. High transient startup torques and misalignment caused by skewed rotational axes between driver and driven in electric motor, hydraulic and pneumatic drives also cause high imposed forces on driven components. These unwanted forces loosen bolted joints and cause spline fretting, clutch disk wear, bearing failure, gear tooth fatigue and shaft fatigue, among an array of other problems.

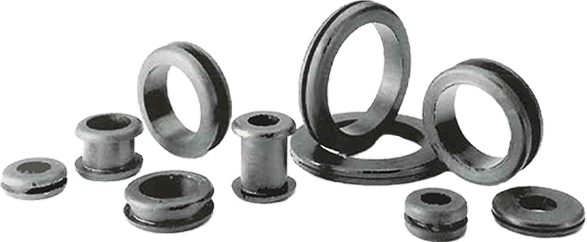

Elastomeric flexible couplings solve these problems. They prolong driveline component life because they reduce the magnitude of imposed loads, attenuate vibration in multiple planes, accommodate misalignments in multiple planes, and act as barriers impeding noise created by meshing gears, engaging clutches, etc.

Elastomeric flexible couplings are also maintenance-free. They require no lubrication or other maintenance throughout their service life. Among the large variety of coupling types available, Lord’s elastomeric couplings offer the most comprehensive package of benefits available to the powertrain designer. Lord’s product lines include five different elastomeric coupling styles which cover a wide range of application requirements.

Lord offers five major lines of elastomeric flexible couplings. In addition to the standards listed, many variations are available in each product line.

|