| Items |

CBA12-100-50

CBA-50 Series Center Bonded Mounts

|

CBA12-200-50

CBA-50 Series Center Bonded Mounts

|

CBA20-300-50

CBA-50 Series Center Bonded Mounts

|

CBA20-400-50

CBA-50 Series Center Bonded Mounts

|

CBA24-500-50

CBA-50 Series Center Bonded Mounts

|

|

Description

|

N/A

- Vibration isolation in all directions.

- Noise attenuation.

- Easy installation because of one-piece design.

- Low-cost installation.

- Long service life.

- Consistent performance because of permanently bonded design.

- Shock protection in all directions provided by cushioned snubbing, no metal-to-metal bottoming.

- Standard sizes available from stock.

- Space-saving size.

- Captive installation after overload failure when recommended bolt, washer and nut are used.

- Accommodate English and Metric bolts.

|

|

Maximum Axial Static Load Rating at Deflection1

|

N/A

100 lbs at 0.09 in 445 N at 2.3 mm

|

N/A

200 lbs at 0.09 in 890 N at 2.3 mm

|

N/A

1334 N at 3 mm 300 lbs at 0.12 in

|

N/A

1780 N at 3 mm 400 lbs at 0.12 in

|

N/A

2224 N at 3 mm 500 lbs at 0.12 in

|

|

Typical Axial Spring Rate

|

N/A

1110 lbs/in194 N/mm

|

N/A

2220 lbs/in389 N/mm

|

N/A

2500 lbs/in438 N/mm

|

N/A

3300 lbs/in578 N/mm

|

N/A

4200 lbs/in736 N/mm

|

|

Typical Radial Spring Rate

|

N/A

1300 lbs/in228 N/mm

|

N/A

3000 lbs/in525 N/mm

|

N/A

3500 lbs/in613 N/mm

|

N/A

4300 lbs/in753 N/mm

|

N/A

5300 lbs/in927 N/mm

|

|

Metal Bracket Part Number2

|

N/A

Y-30266-5-1

|

N/A

Y-30266-5-1

|

N/A

Y-30266-4-1

|

N/A

Y-30266-4-1

|

N/A

Y-30266-3-1

|

|

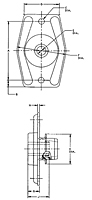

Dimension A

|

N/A

2.38 in60.5 mm

|

N/A

2.38 in60.5 mm

|

N/A

3.75 in95.2 mm

|

N/A

3.75 in95.2 mm

|

N/A

4.25 in108.0 mm

|

|

Dimension B

|

N/A

0.44 in11.2 mm

|

N/A

0.44 in11.2 mm

|

N/A

0.50 in12.7 mm

|

N/A

0.50 in12.7 mm

|

N/A

0.50 in12.7 mm

|

|

Minimum Diameter C

|

N/A

0.404 in10.3 mm

|

|

Maximum Diameter C

|

N/A

0.412 in10.5 mm

|

|

Dimension D

|

N/A

1.75 in44.5 mm

|

N/A

1.75 in44.5 mm

|

N/A

2.25 in57.2 mm

|

N/A

2.25 in57.2 mm

|

N/A

2.50 in63.5 mm

|

|

Minimum Inner Diameter E

|

N/A

0.397 in10.1 mm

|

N/A

0.397 in10.1 mm

|

N/A

0.525 in13.3 mm

|

N/A

0.525 in13.3 mm

|

N/A

0.639 in16.2 mm

|

|

Maximum Inner Diameter E

|

N/A

0.41 in10.4 mm

|

N/A

0.41 in10.4 mm

|

N/A

0.54 in13.7 mm

|

N/A

0.54 in13.7 mm

|

N/A

0.657 in16.7 mm

|

|

Outer Diameter

|

N/A

0.50 in12.7 mm

|

N/A

0.50 in12.7 mm

|

N/A

0.75 in19.0 mm

|

N/A

0.75 in19.0 mm

|

N/A

0.88 in22.3 mm

|

|

Dimension F

|

N/A

2.25 in57.2 mm

|

N/A

2.25 in57.2 mm

|

N/A

3.00 in76.2 mm

|

N/A

3.00 in76.2 mm

|

N/A

3.50 in88.9 mm

|

|

Dimension G

|

N/A

0.61 in15.5 mm

|

N/A

0.61 in15.5 mm

|

N/A

0.85 in21.6 mm

|

N/A

0.85 in21.6 mm

|

N/A

0.82 in20.8 mm

|

|

Dimension H

|

N/A

0.06 in1.5 mm

|

N/A

0.06 in1.5 mm

|

N/A

0.1 in2.5 mm

|

N/A

0.1 in2.5 mm

|

N/A

0.13 in3.3 mm

|

|

Dimension I

|

N/A

1.25 in31.8 mm

|

N/A

1.25 in31.8 mm

|

N/A

2.00 in50.8 mm

|

N/A

2.00 in50.8 mm

|

N/A

2.35 in59.7 mm

|

|

Dimension J

|

N/A

1.07 in27.2 mm

|

N/A

1.07 in27.2 mm

|

N/A

1.45 in36.8 mm

|

N/A

1.45 in36.8 mm

|

N/A

1.50 in38.1 mm

|

|

Dimension K

|

N/A

1.25 in31.8 mm

|

N/A

1.25 in31.8 mm

|

N/A

1.92 in48.8 mm

|

N/A

1.92 in48.8 mm

|

N/A

2.19 in55.6 mm

|

|

Minimum M3

|

N/A

1.50 in38.1 mm

|

N/A

1.50 in38.1 mm

|

N/A

2.38 in60.5 mm

|

N/A

2.38 in60.5 mm

|

N/A

2.75 in69.9 mm

|

|

Dimension N

|

N/A

0.57 in14.5 mm

|

N/A

0.57 in14.5 mm

|

N/A

0.79 in20.1 mm

|

N/A

0.79 in20.1 mm

|

N/A

0.76 in19.3 mm

|

|

Dimension SD (± 0.03)

|

N/A

1.38 in35.1 mm

|

N/A

1.38 in35.1 mm

|

N/A

2.00 in50.8 mm

|

N/A

2.00 in50.8 mm

|

N/A

2.25 in57.2 mm

|

|

Minimum T4

|

N/A

0.19 in4.8 mm

|

N/A

0.19 in4.8 mm

|

N/A

0.25 in6.4 mm

|

N/A

0.25 in6.4 mm

|

N/A

0.38 in9.7 mm

|

|

Maximum T5

|

N/A

0.25 in6.40 mm

|

N/A

0.25 in6.40 mm

|

N/A

0.38 in9.70 mm

|

N/A

0.38 in9.70 mm

|

N/A

0.50 in12.7 mm

|

|

Washer Part Number

|

N/A

J-2049-58

|

N/A

J-2049-58

|

N/A

J-2049-52

|

N/A

J-2049-52

|

N/A

J-2049-53

|

|

Inner Diameter

|

N/A

0.42 in10.7 mm

|

N/A

0.42 in10.7 mm

|

N/A

0.53 in13.5 mm

|

N/A

0.53 in13.5 mm

|

N/A

0.64 in16.3 mm

|

|

Thickness

|

N/A

0.120 in3.0 mm

|

N/A

0.120 in3.0 mm

|

N/A

0.125 in3.2 mm

|

N/A

0.125 in3.2 mm

|

N/A

0.125 in3.2 mm

|

|

Tolerances for Dimensions

|

N/A

.xx = ± 0.03 in. (± 0.762 mm)

.xxx = ± 0.015 in. (± 0.381 mm)

|

|

Washer

|

N/A

J-2049-58, Washer

|

N/A

J-2049-58, Washer

|

N/A

J-2049-52, Head Washer

|

N/A

J-2049-52, Head Washer

|

N/A

J-2049-53, Head Washer

|

|

General Description

|

N/A

Center Bonded Mounts provide flexible suspension systems for mobile, transport-mounted or portable equipment. Typical applications include engines, cabs, fuel tanks, pumps, air conditioning units, compressors and industrial machinery.

|

|

Application Engineering Assistance

|

N/A

Frequently, vibration isolation problems require a system engineering analysis. Lord has the computer capability, as well as specialized programs, for analyzing engine/ transmission combinations. The output from this analysis is a mounting proposal which optimizes performance over the complete range of operating speeds. This service is available to you upon request.

|

|

Note

|

N/A

Mount and washer only furnished by Lord.

All metal parts are made of low carbon steel.

|