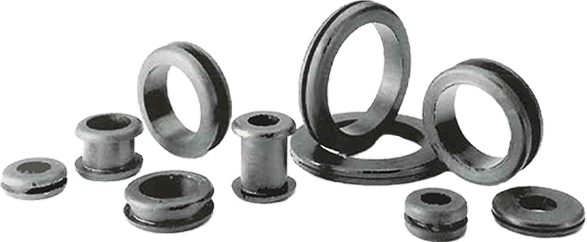

- High-efficiency, multi-directional isolation of low frequency vibration.

- Extremely rugged and require no maintenance.

- Easily installed.

- Long service life.

Specifications

Maximum Axial Load |

N/A 750 to 1500 lbs3336 to 6672 N |

Deflection at Maximum Axial Load |

N/A 0.03 in0.762 mm |

Dimension A |

N/A 2.50 in63.5 mm |

Diameter C |

N/A 0.656 in16.7 mm |

Dimension D |

N/A 1.19 in30.2 mm |

Dimension E |

N/A 5/8-11 UNC-2B |

Dimension F |

N/A 5.5 in139.7 mm |

Dimension G |

N/A 7 in177.8 mm |

Material |

N/A Parts made of Neoprene Elastomer. |

General Description

|

N/A

Lattice Mounts are recommended for applications where disturbing frequencies are as low as 6 Hz. Their lattice design provides a soft vertical spring rate combined with lateral stability. Typical applications include shakerscreens, sifters, rubber mills, air compressors and large engines/generators. |

Installation

|

N/A Each Lord Shock Mount is only 1-3/16" (30.16mm) high. It requires minimal lifting of machinery, and does not shift the machine's center of gravity. The top plate of each Shock Mount is tapped to receive a standard 5/8-11UNC-2B bolt for attaching to the machine. Through holes are provided on each side of the bottom plate extension for bolting the Shock Mount to the floor. |

Vibration Problems

|

N/A Lord Shock Mounts are specifically engineered to isolate vertical shocks and reduce transmission of structural noise through floors. If your application involves intermittent or continuous vibration frequencies above 600 cycles per minute, use Lord Chan-L™ Mounts. If frequencies below 600 cycles per minute are involved, use Lord Lattice Mountings. |