Dynaflex® LCR Series Couplings

Couplings

For Angular Misalignment, Torsional Vibration and Shock Protection

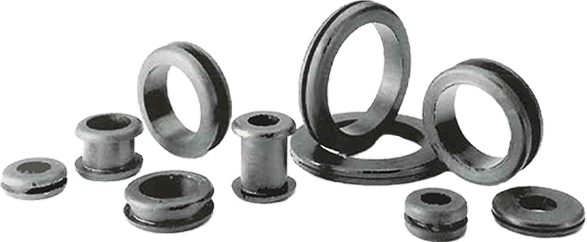

A series of highly flexible elastomeric couplings for accessory drives designed to eliminate lubrication and maintenance.

A series of highly flexible elastomeric couplings for accessory drives designed to eliminate lubrication and maintenance.

Unit of Measure

| Items |

/Asset/a1239.jpg /Asset/a1239.jpg LCR-275-400-004A Dynaflex® LCR Series Couplings |

/Asset/a1239.jpg /Asset/a1239.jpg LCR-275-400-009A Dynaflex® LCR Series Couplings |

/Asset/a1239.jpg /Asset/a1239.jpg LCR-275-400-017A† Dynaflex® LCR Series Couplings |

/Asset/a1239.jpg /Asset/a1239.jpg LCR-300-600-028A† Dynaflex® LCR Series Couplings |

/Asset/a1239.jpg /Asset/a1239.jpg LCR-300-600-046A Dynaflex® LCR Series Couplings |

|||||

| Description |

N/A

The ring-type coupling line has been developed to overcome numerous torsional problems associated with vehicular and industrial driveline systems. The result is increased equipment life by protecting against torsional vibration, shock and misalignment. Significant benefits are:

|

|||||||||

| Shaft Rating at 2000 rpm | N/A 4 to 35 hp | |||||||||

| Torque Rating | N/A 125 lbs-in14 N-m | N/A 290 lbs-in33 N-m | N/A 550 lbs-in62 N-m | N/A 880 lbs-in99 N-m | N/A 1440 lbs-in163 N-m | |||||

| Power per 100 rpm | N/A 0.20 hp0.15 kW | N/A 0.46 hp0.34 kW | N/A 0.87 hp0.65 kW | N/A 1.40 hp1.04 kW | N/A 2.28 hp1.70 kW | |||||

| Capacity at 1750 rpm | N/A 3.5 hp2.6 kW | N/A 8.1 hp6.0 kW | N/A 15.3 hp11.4 kW | N/A 24.4 hp18.2 kW | N/A 40.0 hp29.8 kW | |||||

| Capacity at 2000 rpm | N/A 4.0 hp3.0 kW | N/A 9.2 hp6.9 kW | N/A 17.5 hp13.0 kW | N/A 27.9 hp20.8 kW | N/A 45.7 hp34.1 kW | |||||

| Capacity at 3600 rpm | N/A 7.1 hp5.3 kW | N/A 16.6 hp12.4 kW | N/A 31.4 hp23.4 kW | N/A 50.3 hp37.5 kW | N/A 82.3 hp61.3 kW | |||||

| Static Torsional Rate - K θ | N/A 630 lbs-in/rad71 N-m/rad | N/A 1000 lbs-in/rad113 N-m/rad | N/A 2750 lbs-in/rad311 N-m/rad | N/A 9400 lbs-in/rad1062 N-m/rad | N/A 18000 lbs-in/rad2034 N-m/rad | |||||

| Axial Rate - KA | N/A 150 lbs/in26 N/mm | N/A 350 lbs/in60 N/mm | N/A 950 lbs/in166 N/mm | N/A 1000 lbs/in175 N/mm | N/A 2300 lbs/in404 N/mm | |||||

| Radial Rate - KR | N/A 375 lbs/in66 N/mm | N/A 850 lbs/in149 N/mm | N/A 1300 lbs/in228 N/mm | N/A 1500 lbs/in263 N/mm | N/A 4500 lbs/in790 N/mm | |||||

| Permissible Angular Misalignment | N/A ± 5 º | N/A ± 4 º | N/A ± 3 º | N/A ± 3 º | N/A ± 2 º | |||||

| Permissible Axial Misalignment | N/A ± 1/8 in3.18 mm | N/A ± 3/32 in2.38 mm | N/A ± 3/64 in1.19 mm | N/A ± 3/64 in1.19 mm | N/A ± 1/16 in1.59 mm | |||||

| Permissible Parallel Misalignment | N/A ± 1/16 in1.59 mm | N/A ± 1/16 in1.59 mm | N/A ± 1/32 in0.79 mm | N/A ± 1/32 in0.79 mm | N/A ± 1/32 in0.79 mm | |||||

| Weight | N/A 0.52 lbs0.236 kg | N/A 0.52 lbs0.236 kg | N/A 1.00 lbs0.454 kg | N/A 0.91 lbs0.413 kg | N/A 0.91 lbs0.413 kg | |||||

| Inertia1 | N/A 0.0020 lbs-in- sec2226 kg-mm | N/A 0.0020 lbs-in- sec2226 kg-mm | N/A 0.0038 lbs-in- sec2430 kg-mm | N/A 0.0041 lbs-in- sec2463 kg-mm | N/A 0.0041 lbs-in- sec2463 kg-mm | |||||

| Number of Inserts | N/A 4 | N/A 4 | N/A 4 | N/A 6 | N/A 6 | |||||

| B.C. Diameter A | N/A 2.75 in69.85 mm | N/A 2.75 in69.85 mm | N/A 2.75 in69.85 mm | N/A 3.00 in76.20 mm | N/A 3.00 in76.20 mm | |||||

| Hole Diameter B | N/A 0.32 in8.13 mm | N/A 0.32 in8.13 mm | N/A 0.32 in8.13 mm | N/A 0.39 in9.91 mm | N/A 0.39 in9.91 mm | |||||

| Coupling Inner Diameter C | N/A 4.00 in101.60 mm | N/A 4.00 in101.60 mm | N/A 4.00 in101.60 mm | N/A 4.06 in103.12 mm | N/A 4.06 in103.12 mm | |||||

| Coupling Inner Diameter D | N/A 1.62 in41.15 mm | N/A 1.62 in41.15 mm | N/A 1.62 in41.15 mm | N/A 1.88 in47.75 mm | N/A 1.88 in47.75 mm | |||||

| Length E | N/A 1.00 in25.40 mm | N/A 1.00 in25.40 mm | N/A 1.75 in44.45 mm | N/A 1.53 in38.86 mm | N/A 1.53 in38.86 mm | |||||

| Insert Diameter F | N/A 0.91 in23.11 mm | N/A 0.91 in23.11 mm | N/A 0.91 in23.11 mm | N/A 1.00 in25.40 mm | N/A 1.00 in25.40 mm | |||||

| Length G | N/A 0.12 in3.18 mm | |||||||||

| Length H | N/A 0.75 in19.05 mm | N/A 0.75 in19.05 mm | N/A 1.50 in38.10 mm | N/A 1.28 in32.50 mm | N/A 1.28 in32.50 mm | |||||

| General Description |

N/A

Dynaflex LCR Coupling capacity is rated from 4 to 135 hp at 2000 rpm. These easily installed couplings reduce noise transmission and increase bearing and driveline life through:

Single coupling arrangement consists of two shafts jointed by a single coupling for maximum economy. Double coupling/series arrangement uses two couplings separated by a floating shaft. This provides same torque capacity as single hub arrangement, with twice the permissible angular misalignment and half the torsional stiffness. Superior to single coupling for control of torsional vibration. |

|||||||||

| Note |

N/A

Torque Requirements: Torque (lbs.-in.) = 63025 x hp/rpm Lord does not supply hubs. Lord supplies ring elements only. |

N/A

Torque Requirements: Torque (lbs.-in.) = 63025 x hp/rpm Lord does not supply hubs. Lord supplies ring elements only. |

N/A

Torque Requirements: Torque (lbs.-in.) = 63025 x hp/rpm Non-Stock Item, please contact Lord Corporation for availability Lord does not supply hubs. Lord supplies ring elements only. |

N/A

Torque Requirements: Torque (lbs.-in.) = 63025 x hp/rpm Non-Stock Item, please contact Lord Corporation for availability Lord does not supply hubs. Lord supplies ring elements only. |

N/A

Torque Requirements: Torque (lbs.-in.) = 63025 x hp/rpm Lord does not supply hubs. Lord supplies ring elements only. |

|||||

|

||||||||||