Dynaflex® Elastomeric Flexible Couplings

Couplings

Efficient power transmission and driveline component durability are among powertrain designers’ most important concerns. Increased durability and up-time are two characteristics demanded by purchasers of today’s complex and expensive machinery. These demands can only be met with reliable, trouble-free, smooth-running powertrains free from damaging loads which compromise component life.

Unit of Measure

| Items |

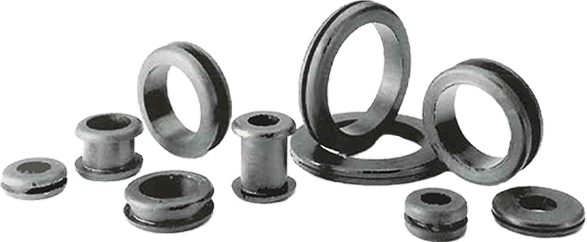

/Asset/a1129.jpg /Asset/a1129.jpg item-1802 Dynaflex® Shear |

/Asset/a1130.jpg /Asset/a1130.jpg item-1803 Dynaflex Spool |

/Asset/a1131.jpg /Asset/a1131.jpg item-1804 Dynaflex® Bushing |

/Asset/a1132.jpg /Asset/a1132.jpg item-1805 Dynaflex® LCR |

/Asset/a1128.jpg /Asset/a1128.jpg item-1806 Dynaflex® LCD |

|||||

| Description | N/A The Dynaflex shear coupling features a durable elastomeric flexing element bonded between two hubs. These couplings are designed for fractional horsepower applications requiring smooth starting transition, torsional vibration isolation and misalignment accommodation. Typical applications are small electric motor drives, low-torque mechanisms, power take-offs and auxiliary equipment drives. | N/A Dynaflex shear spool elements can be arranged in a variety of configurations to create a wide range of torque transmitting capability. Elastomeric spool elements can be purchased in lot sizes for customer-assembled coupling designs, or Lord can provide a complete coupling assembly to meet specific application requirements. Typical applications are large drives requiring high torque capacity and low torsional stiffness. | N/A Dynaflex compression bushings are bonded elastomeric elements designed for use in multiple element coupling configurations where high torque capacity is required. Bushings are available in a variety of stiffnesses. They can be purchased in lots for customer-assembled designs, or Lord can provide complete coupling assemblies designed to meet your specific application requirements. Applications requiring high torque/high torsional stiffness, but angular, axial and parallel misalignment accommodation can be designed using these bushings in a variety of configurations including parallel and series arrangements. | N/A The Dynaflex LCR series features an elastomeric ring with bonded, bush-type inserts allowing various attachment configurations. These couplings offer a soft torsional spring rate which permits smooth transmission of driving torque while attenuating shock torques and providing excellent misalignment accommodation. These couplings are used in PTO drives where torsion and cocking flexibility are required. They can be mated with a variety of hub configurations. Special high-torque designs are available, as well as custom designs to meet special application requirements. | N/A The Lord Dynaflex LCD is the ultimate coupling for reciprocating engine drives. This coupling features a bonded elastomeric flexing element which is radially precompressed into a flanged outer housing. This design produces a low torsional stiffness for maximum isolation of engine firing-pulse-induced torsional disturbances, torque overload slip protection, misalignment accommodation, superior shock pulse attenuation and fatigue life, and is adaptable to a variety of drive attachment designs. Custom designs are available to fit nearly every SAE flywheel configuration available from most engine manufacturers. | |||||

| Horsepower Rated | N/A 1/50 to 1 hp | N/A 50 to 1000 hp | N/A 10 to 600 hp | N/A 4 to 135 hp | N/A 75 to 2000 hp | |||||

| Best Application Area | N/A Low-frequency vibration, multidirectional misalignment | N/A Low-frequency vibration, high-power drive systems | N/A Multidirectional misalignment, high capacity | N/A Large misalignment, safetied drive requirements | N/A Diesel engines, low- frequency vibration, multi-directional misalignment | |||||

| Outstanding Capabilities | N/A Effectively accommodates combinations of misalignment, high torsional resilience | N/A Versatility in design for exact application requirements (stiffness and capacity) | N/A High torque capacity versus size | N/A Angular misalignment capability | N/A Fits many standard flywheels, high torsional resilience | |||||

| Versatility Factor | N/A Widest application potential of all elastomeric couplings | N/A Capacity and resilience can be varied by changing number and type of spool | N/A Numerous combinations possible simply by changing flexing elements | N/A Torsional spring rate varied by changing modulus or wall thickness | N/A Large horsepower, high horsepower capacity | |||||

| Fail-Safe Characteristics | N/A Easily incorporated | N/A Easily incorporated | N/A Inherent | N/A Inherent | N/A Slip-torque feature | |||||

| General Description |

N/A

Powertrain component life is determined by the load spectrum each component will experience during the machine’s service life. Reciprocating engines, such as spark-ignited gasoline and compression-ignited diesels, produce alternating torque loads which, when superimposed on the steady driving torque, create alternating stresses in driveline system components which shorten component life and reliability. High transient startup torques and misalignment caused by skewed rotational axes between driver and driven in electric motor, hydraulic and pneumatic drives also cause high imposed forces on driven components. These unwanted forces loosen bolted joints and cause spline fretting, clutch disk wear, bearing failure, gear tooth fatigue and shaft fatigue, among an array of other problems. Elastomeric flexible couplings solve these problems. They prolong driveline component life because they reduce the magnitude of imposed loads, attenuate vibration in multiple planes, accommodate misalignments in multiple planes, and act as barriers impeding noise created by meshing gears, engaging clutches, etc. Elastomeric flexible couplings are also maintenance-free. They require no lubrication or other maintenance throughout their service life. Among the large variety of coupling types available, Lord’s elastomeric couplings offer the most comprehensive package of benefits available to the powertrain designer. Lord’s product lines include five different elastomeric coupling styles which cover a wide range of application requirements. Lord offers five major lines of elastomeric flexible couplings. In addition to the standards listed, many variations are available in each product line. |

|||||||||

| Application |

N/A

Application requirements suggest the coupling style needed to optimize powertrain performance and component longevity. Misalignment accommodation, torsional vibration isolation, transient shock dissipation and required service life are important parameters to consider when selecting a coupling to fill specific application requirements. Lord engineers can assist you with selecting an appropriate coupling type and configuration. With extensive analytical capability and years of experience in designing products for powertrain vibration, shock and motion control, Lord engineers offer everything from simple application assistance to complex system analysis and specialized product design. Torsional vibration, transient shock and misalignment load analyses require specialized computer programs and engineering experience. Lord engineers can analyze your system and recommend the right solution, whether it's a selection from the standard product line or a custom design. Lord’s standard product lines of elastomeric flexible powertrain couplings are presented in the following sections. Many variations of standard products are available, but not listed as ‘standard.’ Main drive, fan drive, PTO and accessory drive couplings are available in a host of custom designs and variations of standard products. Lord engineers are ready to help you meet your specific application requirements with custom designs where necessary. |

|||||||||

|

|

||||||||||