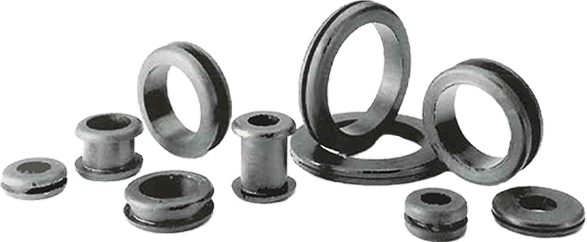

Center Bonded Bushings

Bushings

Center Bonded Bushings and Square Bonded Bushings are used in applications where the absorption shock, attenuation of noise, reduction of wear and elimination of lubrication is required.

Unit of Measure

| Items |

/Asset/a1106.jpg /Asset/a1106.jpg J-3830-13 Center Bonded Bushings with Outer Member |

/Asset/a1106.jpg /Asset/a1106.jpg J-5385-31 Center Bonded Bushings with Outer Member |

/Asset/a1106.jpg /Asset/a1106.jpg J-6729-2 Center Bonded Bushings with Outer Member |

/Asset/a1106.jpg /Asset/a1106.jpg J-6740-3 Center Bonded Bushings with Outer Member |

/Asset/a1106.jpg /Asset/a1106.jpg J-3830-6 Center Bonded Bushings without Outer Member |

|||||

| Description |

N/A

|

|||||||||

| Maximum Radial Static Load Rating | N/A 300 lbs1334 N | N/A 1000 lbs4448 N | N/A 6000 lbs26689 N | N/A 9300 lbs41368 N | N/A 200 lbs890 N | |||||

| Spring Rate Radial (K rad) | N/A 14000 lbs/in2451 N/mm | N/A 36600 lbs/in6408 N/mm | N/A 150000 lbs/in26265 N/mm | N/A 256000 lbs/in44825 N/mm | N/A 13700 lbs/in2398 N/mm | |||||

| Torsional | N/A 3.6 lbs-in/deg0.6 N-mm/deg | N/A 18.7 lbs-in/deg3.3 N-mm/deg | N/A 119 lbs-in/deg20.8 N-mm/deg | N/A 475 lbs-in/deg83.2 N-mm/deg | N/A 4.8 lbs-in/deg0.8 N-mm/deg | |||||

| Recommended Socket Diameter (± 0.001) | N/A 1.245 in | N/A 1.743 in | N/A 1.996 in | N/A 3.231 in | N/A | |||||

| Recommended Socket Diameter | N/A 31.6 mm | N/A 44.3 mm | N/A 50.7 mm | N/A 82.1 mm | N/A | |||||

| Recommended Socket Diameter (± 0.015 (±0.38 mm)) | N/A | N/A | N/A | N/A | N/A 1.06 in27.05 mm | |||||

| Recommended Socket Length | N/A 0.88 in22.35 mm | N/A 2.00 in50.80 mm | N/A 4.00 in101.60 mm | N/A 4.00 in101.60 mm | N/A 0.88 in22.35 mm | |||||

| Dimension A | N/A 0.516 in13.1 mm | N/A 0.504 in12.8 mm | N/A 1.129 in28.7 mm | N/A 1.500 in38.1 mm | N/A 0.517 in13.1 mm | |||||

| Dimension B | N/A 1.253 in31.8 mm | N/A 1.75 in44.5 mm | N/A 2.004 in50.9 mm | N/A 3.234 in82.1 mm | N/A 1.12 in28.4 mm | |||||

| Dimension C | N/A 1.00 in25.4 mm | N/A 2.62 in66.5 mm | N/A 4.25 in108.0 mm | N/A 7.50 in190.5 mm | N/A 1.00 in25.4 mm | |||||

| Dimension D | N/A 0.75 in19.1 mm | N/A 1.00 in25.4 mm | N/A 1.31 in33.3 mm | N/A 2.12 in53.8 mm | N/A 0.75 in19.1 mm | |||||

| General Description |

N/A

Center Bonded Bushings are designed to be loaded radially and utilize a soft torsional spring rate to provide freedom in rotation. High radial restraint maintains the alignment between joined parts. They are not intended for use where extreme rotational motion will occur. Typical applications include heavy duty highway equipment, drilling equipment, harvesters, combines and industrial machinery. Square Center Bonded Bushings accommodate angular movement and isolate vibratory disturbances in heavy equipment. These bushings combine a torsional spring with an elastomeric pivot and isolator. They provide positive torsional positioning and pivot action under the most demanding operating conditions. Typical applications include wheel suspensions, vibratory feeders, mobile power equipment and vibratory cable layers. Easy to install, the uncomplicated designs of the Center Bonded and Square Bonded Bushings provide initial economy, while the rugged elastomers and high strength bonding assure extended service life. |

|||||||||

| Note |

N/A

First determine the amount of static loading at the installation point. Then determine the conditions under which the joint will operate. The following should be used as a guide to part selection for Type "A" and Type "B" service. TYPE A: Extreme conditions (reversing dynamic load or distortion at high frequency - over 600 cpm) use 1/3 the Radial Static Load Rating. TYPE B: Average conditions (constant radial load, intermittent shock) use the Radial Static Load Rating. |

|||||||||

|

|

||||||||||