All Categories

all-categories

The Fluidlastic mount concept allows the use of a softer mount for better isolation of vibration and uses internal fluid damping to reduce motions at resonant conditions or shock inputs. Fluidlastic mounts offer tuneable damping. The level of damping and the frequency where the peak damping occurs can be specified. A variety of fluids and orifice configurations create this damper effect. Not only does the fluid provide damping in the amplification region, it also provides very low damping in the isolation region.

Another important feature of the Fluidlastic mount is a conveniently packaged tuned absorber. Fluid movement within the mount as it is deflected becomes a tuned mass at a specific frequency or frequency band. This absorber effect is accomplished by the porting and geometry of the fluid path within the mount. The result is a dynamic stiffness that is considerably softer than the static stiffness for that frequency range. This feature is especially useful in improving isolation of noise or vibration at a predominant frequency.

Lord’s design experience along with our test and analytical capability makes Lord the leader in the field of a new generation of mounts. Contact Lord Engineering to review your job application requirements.

Introducing a new generation of mounts. Fluidlastic mounts combine rubber and fluids to provide vibration isolation and noise reduction measurably better than conventional mounts. They also provide greater versatility because the mounts are tuned to precisely match application requirements. This new generation of mounts will help you solve tough vibration and noise problems.

Three-In-One Performance

The Fluidlastic mount is three mounts in one depending upon the frequency and amplitude of the excitation. First, it’s a spring providing basic load and motion capability to the system. Second, it’s a damper providing restricted motion at or near resonant conditions. And thirdly, it’s a tuned absorber providing superior isolation at a specific frequency.

Fluidlastic mounts are rubber mounts which encapsulate a fluid that flows through a variety of ports and orifices depending upon the dynamic characteristics needed. The result is a very versatile and effective vibration isolator. /Asset/a1035.jpg

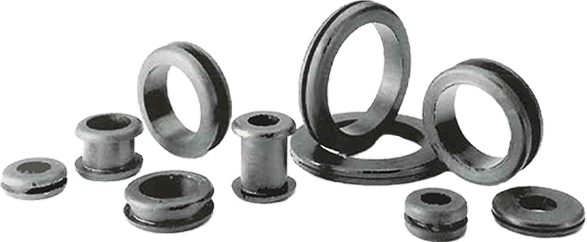

Use our Stock Grommets in your application to save time and money.

If your grommet is not in the MS Number, call and we can cross the MS-35489 Series to the AN-931 {Army-Navy Standard Grommets) and also the MS-35490 (Military Standard Split Grommets.)

Ordering grommets under these specifications should include a waiver of Samples Test required by revisions MIL-G-3036. Certifications must be requested at the time of order. We do not charge for these certificates. If testing requirements are unusually strict, laboratory fees may apply. /Asset/a1001.jpg

Low minimum orders for stocked parts. /Asset/a1178.jpg

Lord Vibration Mounts

Why They Out-Perform Conventional Rubber MountsThe Fluidlastic mount concept allows the use of a softer mount for better isolation of vibration and uses internal fluid damping to reduce motions at resonant conditions or shock inputs. Fluidlastic mounts offer tuneable damping. The level of damping and the frequency where the peak damping occurs can be specified. A variety of fluids and orifice configurations create this damper effect. Not only does the fluid provide damping in the amplification region, it also provides very low damping in the isolation region.

Another important feature of the Fluidlastic mount is a conveniently packaged tuned absorber. Fluid movement within the mount as it is deflected becomes a tuned mass at a specific frequency or frequency band. This absorber effect is accomplished by the porting and geometry of the fluid path within the mount. The result is a dynamic stiffness that is considerably softer than the static stiffness for that frequency range. This feature is especially useful in improving isolation of noise or vibration at a predominant frequency.

Lord’s design experience along with our test and analytical capability makes Lord the leader in the field of a new generation of mounts. Contact Lord Engineering to review your job application requirements.

Introducing a new generation of mounts. Fluidlastic mounts combine rubber and fluids to provide vibration isolation and noise reduction measurably better than conventional mounts. They also provide greater versatility because the mounts are tuned to precisely match application requirements. This new generation of mounts will help you solve tough vibration and noise problems.

Three-In-One Performance

The Fluidlastic mount is three mounts in one depending upon the frequency and amplitude of the excitation. First, it’s a spring providing basic load and motion capability to the system. Second, it’s a damper providing restricted motion at or near resonant conditions. And thirdly, it’s a tuned absorber providing superior isolation at a specific frequency.

Fluidlastic mounts are rubber mounts which encapsulate a fluid that flows through a variety of ports and orifices depending upon the dynamic characteristics needed. The result is a very versatile and effective vibration isolator. /Asset/a1035.jpg

Stock Grommets

(127) Stock grommets are available in 60 durometer black SBR. Listed below by increasing Inside Diameter (A) are the grommets that are considered stock items. Check our manufactured grommet section if you cannot find a particular item in this section. Low minimum orders for stocked parts.Use our Stock Grommets in your application to save time and money.

- If you can't find the part you are looking for in this catalog, please call. We have the capability to make any part you need.

- Our goal is to have your grommet in stock when you need it, whether it's a standard stock part or one of your custom part requirements.

- When you need help in determining the type of rubber to use, call us and we'll gladly help you find the optimal material for your application.

- When you need to see and fit the grommet into your application, we'll sample parts for your evaluation.

- Use grommets to eliminate wear on electrical wiring running through sharp holes.

- Grommets can be used to make a seal around pipes or wiring.

- Grommets can be used cosmetically, making drilled or punched holes look better.

- Grommets can be used under light equipment to reduce noise and vibration.

Military Grommets

(135) Military grommets are available in rubber material that is hot oil & coolant-resistant. Listed below by increasing Inside Diameter (ID) are the military grommets that are considered stock items. Specification: MIL-G-3036.If your grommet is not in the MS Number, call and we can cross the MS-35489 Series to the AN-931 {Army-Navy Standard Grommets) and also the MS-35490 (Military Standard Split Grommets.)

Ordering grommets under these specifications should include a waiver of Samples Test required by revisions MIL-G-3036. Certifications must be requested at the time of order. We do not charge for these certificates. If testing requirements are unusually strict, laboratory fees may apply. /Asset/a1001.jpg

Molded Stock Parts

(11) Molded stock parts are available in 60 durometer black SBR. Low minimum orders for stocked parts. /Asset/a1216.jpg

Stock Step Bushings

(15) Step bushings are available in 60 durometer black SBR. Listed below by increasing Inside Diameter (A) are the step bushings that are considered stock items. Check our manufactured step bushings section if you cannot find a particular item in this section.Low minimum orders for stocked parts. /Asset/a1178.jpg

Stock Suction Cups

(12) Stock suction cups are constructed from high quality rubber. Listed below by increasing Cup Diameter (A) are the suction cups that are considered stock items. Check our manufactured suction cup section if you cannot find a particular item in this section. Low minimum orders for stocked parts. /Asset/a1189.jpg