| Items |

J-16461-4

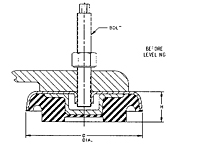

Leveling Mounts

|

J-16462-4

Leveling Mounts

|

J-16462-7

Leveling Mounts

|

|

Maximum Load per Mount

|

N/A

1000 lbs4448 N

|

N/A

4500 lbs20017 N

|

N/A

4500 lbs20017 N

|

|

Adjusting Bolt

|

N/A

1/2 - 13 UNC x 5 in127 mm

|

N/A

3/4 - 10 UNC x 5 in127 mm

|

N/A

3/4 - 10 UNC x 5 in127 mm

|

|

Dimension D

|

N/A

4-3/4 in120.7 mm

|

N/A

6-1/4 in158.8 mm

|

N/A

6-1/4 in158.8 mm

|

|

Dimension H - Height (Free)

|

N/A

1-1/2 in38.1 mm

|

N/A

1-5/8 in41.3 mm

|

N/A

1-5/8 in41.3 mm

|

|

Weight

|

N/A

2.5 lbs1.1 kg

|

N/A

5.0 lbs2.3 kg

|

N/A

5.0 lbs2.3 kg

|

|

Maximum Adjustment1

|

N/A

1/2 in12.7 mm

|

|

Vertical Natural Frequency

|

N/A

12 Hz

|

|

General Description

|

N/A

Lattice Mounts are recommended for applications where disturbing frequencies are as low as 6 Hz. Their lattice design provides a soft vertical spring rate combined with lateral stability. Typical applications include shakerscreens, sifters, rubber mills, air compressors and large engines/generators.

Chan-L™ Mounts are recommended for machines where vertical disturbing frequencies are 600 cpm or higher. Their elastomer-supported channel design features a soft vertical spring rate. The design incorporates built-in protection against metal-to-metal bottoming. Typical applications include separating and grading screens and shakeouts.

Leveling Mounts provide the ability to level equipment and machinery. These mounts offer a vertical natural frequency under maximum load of 12 Hz. They are constructed of a neoprene elastomer, which resists oil, ozone and caustic materials, and a high-visibility yellow housing made of high strength steel.

Industrial Shockmounts efficiently control shock and structural noise transmission from heavy industrial machinery. Adjacent controls, sensitive instruments and precision machines are protected from impact disturbances which could hamper their performance. Worker comfort is increased, and building structures need less maintenance.

|

|

Installation

|

N/A

Before installing, be sure the mounts are the right ones for your machine.- Remove adjusting bolt and lock nut from mount.

- Raise machine and slide mount under foot.

- Insert adjusting bolt through clearance hole in foot and engage threads in mount.

- Lower machine onto mounts.

- Turn bolt until it bottoms.

To Level:- Level machine by turning the adjusting bolt.

- Tighten lock nut against machine base.

|

|

Note

|

N/A

Metal housing made of high strength steel - high visibility yellow paint (OSHA approved). Elastomer: neoprene compounded to resist oil, ozone and caustic material.

Adjustment bolt and lock nut included.

|

N/A

Metal housing made of high strength steel - high visibility yellow paint (OSHA approved). Elastomer: neoprene compounded to resist oil, ozone and caustic material.

Adjustment bolt and lock nut included.

|

N/A

Metal housing made of high strength steel - high visibility yellow paint (OSHA approved). Elastomer: neoprene compounded to resist oil, ozone and caustic material.

Adjustment bolt and lock nut included.

J-16462-7 has stainless steel bolt and hardware.

|