- Easy to install.

- Uncomplicated design provides initial economy.

- High-strength bonding assures extended service life.

- Minimal maintenance due to specially compounded elastomer

Specifications

Maximum Radial Static Load Rating |

N/A 1125 lbs5004 N |

Spring Rate Radial (K rad) |

N/A 40000 lbs/in7004 N/mm |

Torsional |

N/A 94 lbs-in/deg16.5 N-mm/deg |

Recommended Socket Diameter (± 0.015 (±0.38 mm)) |

N/A 2.22 in56.38 mm |

Recommended Socket Length |

N/A 1.88 in47.75 mm |

Dimension A |

N/A 1.316 in33.4 mm |

Dimension B |

N/A 2.39 in60.7 mm |

Dimension C |

N/A 2.24 in56.9 mm |

Dimension D |

N/A 1.50 in38.1 mm |

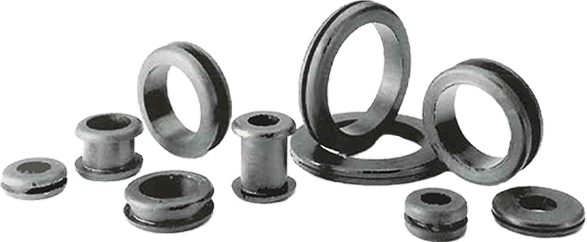

General Description

|

N/A

Center Bonded Bushings are designed to be loaded radially and utilize a soft torsional spring rate to provide freedom in rotation. High radial restraint maintains the alignment between joined parts. They are not intended for use where extreme rotational motion will occur. Typical applications include heavy duty highway equipment, drilling equipment, harvesters, combines and industrial machinery. |

Note

|

N/A

First determine the amount of static loading at the installation point. Then determine the conditions under which the joint will operate. The following should be used as a guide to part selection for Type "A" and Type "B" service. |